Why it is important to prevent moisture for rare earth?

International movie star Zhang Ziyi changed her Sina Weibo(one of the biggest social media platforms of China)name to her real name. Her initial name of Sina Weibo is “rare-earth troops”, for the elements are rare and valuable materials.

A rare-earth element or rare-earth metal, as defined by the International Union of Pure and Applied Chemistry, is one of a set of seventeen chemical elements in the periodic table, specifically the fifteen lanthanides, as well as scandium and yttrium.Rare earths are vital to many modern technologies, including consumer electronics, computers and networks, communications, clean energy, advanced transportation, health care, environmental mitigation, national defense, and many others.

Rare earths are widely used in daily life such as components assembly, chips, cell phone screen, digital cameras, and even missile, radar and submarine

Components used of rare earths have to be kept in dry environment for utilization.

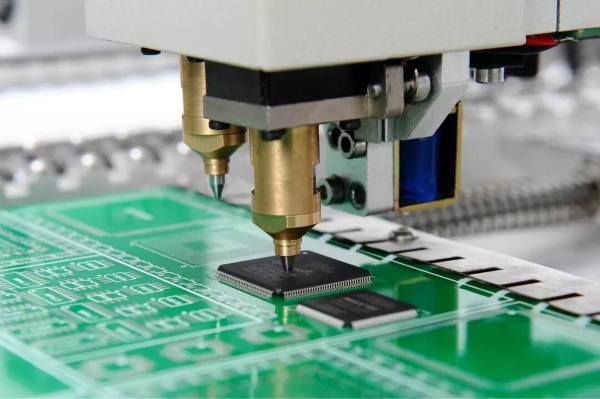

Rare earths relates to SMT industry. Let’s talk about the changes happening in SMT industry.

Keyword: Industry 4.0

There is no doubt that manufacturing still exist in the future. Differing from the past time, it will not be a traditional but a innovative one. Industry 4.0 takes the emphasis on digital technology from recent decades to a whole new level with the help of interconnectivity through the internet, Internet of Things, big data, cloud memory and automation in manufacturing.

Industry 4.0 is a name given to the current trend of automation and data exchange in manufacturing technologies from collective to discrete. It includes cyber-physical systems, the Internet of things, cloud computing and cognitive computing. Industry 4.0 is also sometimes referred to as the fourth industrial revolution in the view of Germany scholars.

Factory Automation is an essential part of Industry 4.0. In fact, for many production facilities, it is the first significant step in the Industry 4.0 journey. Factory automation involves integrating your machines and processes, making better use of data, and designing, developing, and implementing a cyber-physical system in your production. Smart manufacturing refers to the applications in logistics management,human computer interaction and 3D technology in industry manufacturing.

SMT Industry Development

As a new generation electronic mount and connection technology, the trend of SMT is also smart factory and manufacturing. Equipment and robotics will replace the human being for their advantages of low cost, high efficiency and long working time. SMT will be no exception.

Instead of dozens of staffs around the pick and place line, you can see automatic aunloader+Solder paste inspection+automatic printing machine+pick and place machine AOI+reflow soldering+AOI, with auxillary automatic equipments and one or two persons. All the inspection equipments can be remotely controlled. Everything can be finished in the dark so that intelligent equipments are the trends in the coming future.

Industry 4.0 brings great changes to SMT industry. However moisture-preventing is easy to be ignored. What damages will bring to the SMT components? How to prevent SMT components from moisture? Please see the tips below:

Damages of moisture to SMT components

Moisture is the main cause of product quality in SMT industry. The production and storage environment has to be below 40% for SMT. Some kinds of products even require lower humidity. Moisture sensitive materials storing is always a big trouble in all industries.

Damp Electronic components and circuits are easy to cause pseudo soldering when wave soldering . The performance gets worse even the components are baked. A dehumidifier can help you solve the problems.

Ps: the moisture of the integrated circuits becomes vapors when heating in SMT processing. The pressure it causes leads to IC resin package cracks and metal oxidation of the IC components. The vapor pressure when soldering on PCB also causes pseudo soldering.

Other electronic components: capacitor, ceramic device, connector, switch, soldering, PCB , crystal, wafer, quartz oscillater, electrode material adhesive, electronic paste, high brightness device etc., will be damaged by moisture.

End products: the device will cause failure if it is stored in high humidity environment. CUP may oxidize connecting fingers and then failure happens.

How to choose drying cabinets to prevent SMT components from damp?

1Materials of dehumidifier

Industrial dehumidifiers play more and more important tole in SMT industry. Requirement of humidity control and anti-oxidation of chips and metal materials are higher. The first step to choose dehumidifier is to see its material.

Yunboshi dehumidifier: Laser cutting,excellent sealability and 1.2mm cold roll steel

2Humidity controller/display accuracy

Lower humidity environment is required for industrial dehumidifiers storage to prevent moisture and oxidization. However there is no specified anti-oxidization standard.The requirement of anti-oxidization low humidity differs from the products to be stored. The relative humidity of common products on the market is below 10%RH (for ordinary anti-oxidization) or below 5%RH(for higher requirement).

Higher screen display precision plays an more and more important role in lower humidity industrial dehumidifiers. If the display precision is -5%RH or even higher, the equipment does not reach the requirement of within 5%RH. Generally, the precision for most industrial drying cabinets is within -3%RH to -2%RH.

lectronics Co.,Ltd. is a leading industrial and household dehumidifier in China.It absorbs moisture by shape memory. Its drying units are made of high polymer materials and fire-safety PBT. The melting point is 300℃, higher than PPS.

3Humidity Sensor of Drying Cabinets

This core technology of YUNBOSHI has won high reputation in humidity-proof market. The digital humidity and temperature sensor of YUNBOSHI dehumidifier is of SENSIRION, which is famous for its high accuracy from Switzerland. It measures with superb accuracy and no drift with a typical accuracy of ±2% RH

R&D by YUNBOSHI , its chips becomes the first provider intelligently controlling the humidity inside ±5%RH.

4Anti-static Function of Dehumidifier

Anti-static measurements are essential for industrial drying chambers. The common anti-static method is spray coating and grounding. For eternal anti-static effect, spray anti-static powder instead of anti-static paint.

the cabinet surface of YUNBOSHI dehumidifier is eternal(optional function). its controller is anti-fire and with no sound. It can be still working for 24 hours by material substitution when power outage happens.

Dehumidifiers are widely used in SMT industries. No matter a small components or a end product, they help extend the life of electronic products.